Fabric order is the very important role of merchandiser in the factory.

The texture request process in a woven piece of clothing industrial facility is a basic and mind boggling part of the general creation cycle, assuming a vital part in guaranteeing the opportune and productive conveyance of excellent pieces of clothing. This cycle includes a progression of very much organized advances, beginning from the underlying arranging stage to the real obtainment and investigation of textures.

The most vital phase in the texture request process is the making of an exhaustive creation plan. This plan frames the particular prerequisites for each piece of clothing, including the sort of texture, amount required, and any exceptional attributes or medicines required. The creation plan is created in a joint effort with the plan and marketing groups, thinking about variables like occasional patterns, client inclinations, and the specialized details of the pieces of clothing.

When the creation plan is concluded, the following essential step is to recognize and source the suitable textures. This includes liaising with different texture providers, both homegrown and global, to acquire tests and statements. Texture determination is a careful interaction, taking into account factors, for example, fiber content, weave, weight, variety speed, and consistence with quality norms. The objective is to find textures that not just meet the tasteful and useful prerequisites of the pieces of clothing yet in addition line up with the processing plant’s obligation to manageability and moral obtaining rehearses.

After the textures are picked, the industrial facility places orders with the chose providers. This includes arranging costs, lead times, and different terms of the arrangement. Clear correspondence with providers is fundamental to stay away from false impressions and guarantee that the industrial facility gets the ideal quality and amount of textures inside the specified time period. To relieve the gamble of postponements or inconsistencies, numerous production lines keep up serious areas of strength for with solid texture providers, encouraging a feeling of organization that benefits the two players.

When the texture orders are affirmed, the plant intently screens the creation and delivery timetables of the providers. Standard updates and correspondence with providers are kept up with to remain informed about any expected disturbances or deferrals. Now and again, manufacturing plants might decide on airship cargo to speed up the conveyance of basic texture shipments, particularly while neutralizing tight creation courses of events.

Upon the appearance of the textures at the industrial facility, a careful examination process is started. This includes an itemized assessment of the textures for any deformities, irregularities, or deviations from the endorsed tests. Quality control groups evaluate factors like variety precision, winding around imperfections, texture strength, and shrinkage. Any disparities are archived and imparted to the providers for goal. This thorough assessment process is pivotal to keeping up with the exclusive requirements of the completed pieces of clothing and guaranteeing consumer loyalty.

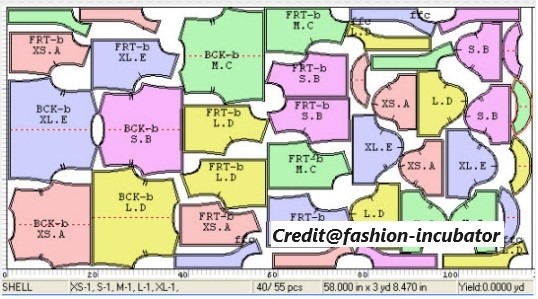

When the textures pass the assessment, they are prepared for the cutting system. The cutting office gets the endorsed textures and follows the markers (designs) given by the example making group. Accuracy is key during the slicing system to limit wastage and guarantee that each article of clothing part is precisely sliced by the predefined aspects. The cut pieces are then packaged and shipped off the sewing division for gathering.

All through the whole texture request process, powerful correspondence and joint effort between different divisions are basic. The creation, quality control, and coordinated operations groups should work as one to address any difficulties that might emerge and to keep the work process consistent. Ordinary gatherings and updates guarantee that everybody in question knows about the situation with texture arranges and can proactively address any issues that might affect the creation course of events.

All in all, the texture request process in a woven piece of clothing production line is a multi-layered and unpredictable excursion that starts with fastidious preparation and finishes with the conveyance of great pieces of clothing. From the underlying creation plan to the last investigation of textures, each step expects scrupulousness, successful correspondence, and joint effort across various divisions. By sticking to rigid quality principles, keeping up major areas of strength for with providers, and focusing on effective work processes, industrial facilities can advance the texture request process and add to the general outcome of the piece of clothing producing industry.