Generally two category of fabrics are used in the garment industry.

Woven fabric

Knitted fabric

Fabrics are made either with weaving process or by knitting process. Fabric which is made through weaving process that called woven fabric and the fabric, which is made through knitting process that is called knitted fabric. For the weaving process, weaving machine like Auto loom, power loom and handloom are used to make the fabric, where as circular knitting machine, flat knitting machine etc are used to make knitted fabric.

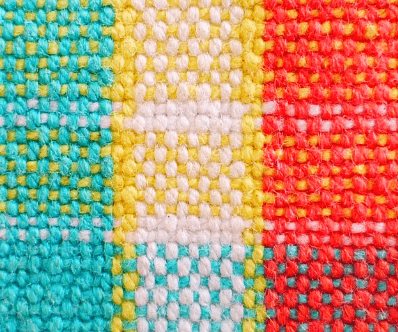

Woven fabric—

Woven texture, a key component in the immense embroidery of material creation, epitomizes the multifaceted transaction of strings and method that has been sharpened over hundreds of years. This flexible material is created through the careful winding of twist and weft strings, bringing about a material that flaunts strength, sturdiness, and many tasteful conceivable outcomes. The historical backdrop of woven texture can be followed back to old civilizations, where gifted craftsmans utilized manual weaving machines make materials that filled both pragmatic and imaginative needs.

At its center, the winding around process includes the intertwining of two arrangements of yarns – the twist, which runs upward, and the weft, which navigates evenly. The twist is commonly the more grounded, more steady arrangement of strings, giving the primary establishment to the texture. The weft, then again, presents tone, example, and surface, making the visual and material parts of the eventual outcome. This amicable interlacing of strings considers the formation of textures with different qualities, going from the freshness of fabric to the non-abrasiveness of wool.

One of the most notable instances of woven texture is denim. Denim, a strong cotton twill texture, has become inseparable from sturdiness and easygoing style. Its particular inclining weave, known as a twill weave, adds to its solidarity and protection from mileage. Denim’s prevalence reaches out a long ways past its utilitarian starting points, developing into a design explanation that rises above social and geological limits. The notorious pants, a staple in closets around the world, owe their reality to the imaginativeness of woven texture.

Silk, another exceptional model, addresses the embodiment of extravagance in the realm of materials. Woven from the fine strings delivered by silkworms, silk texture is worshipped for its smooth surface, sheen, and hanging characteristics. The many-sided designs woven into silk textures, for example, those seen in customary Chinese brocades or Indian saris, exhibit the adaptability and creativity that can be accomplished through the winding around process. Silk’s relationship with lavishness and class has made it a sought after material in the domain of high style and extravagance.

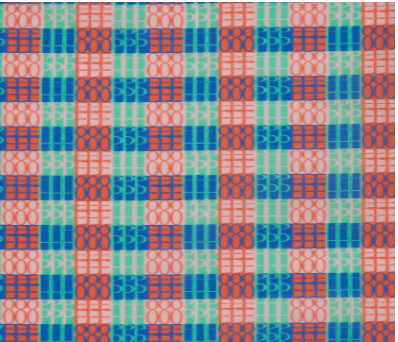

Moving past style, woven textures assume a significant part in inside plan. Take Jacquard texture, for example, which is woven on a specific loom that considers the complex and elaborate examples to be woven straightforwardly into the texture. Named after Joseph Marie Jacquard, who imagined the Jacquard loom in the mid nineteenth hundred years, this winding around procedure empowers the making of definite plans, frequently utilized in upholstery, curtain, and embroidered works of art. The Jacquard loom prepared for the motorization of winding around, denoting a huge achievement throughout the entire existence of material creation.

Woven textures are not restricted to conventional materials like cotton, silk, or fleece; mechanical progressions have introduced a period of advancement and trial and error. Carbon fiber textures, for example, are woven from strands of carbon filaments, making a material known for its excellent strength and low weight. This cutting edge winding around application finds its place in businesses going from aviation to athletic gear, exhibiting the versatility of woven texture across assorted fields.

In the domain of reasonable materials, natural cotton woven textures have acquired noticeable quality. These materials are woven from cotton that is developed without the utilization of engineered pesticides or composts, advancing harmless to the ecosystem and socially capable practices. The meshing of natural cotton strings into texture lines up with the developing consciousness of eco-cognizant shoppers, mirroring a shift towards additional reasonable and moral decisions in the material business.

The meaning of woven texture stretches out past the unmistakable parts of materials. It winds around together social stories, customs, and craftsmanship went down through ages. The multifaceted examples tracked down in ethnic materials, like the Kente material of Ghana or the ikat textures of Focal Asia, recount accounts of legacy and personality. The specialty of winding around, profoundly implanted in the social texture of networks all over the planet, fills in as a demonstration of human imagination and resourcefulness.

Woven texture’s impact isn’t confined to its actual structure; it stretches out to the figurative winding of associations in human social orders. The material business, with its worldwide inventory chains and interconnected economies, represents the complex strings that tight spot countries and societies. From the cotton fields of India to the winding around looms in Italian plants, the excursion of woven texture reflects the interconnectedness of a world woven together by profession, development, and shared encounters.

As we explore the 21st hundred years, the advancement of woven texture proceeds unabated. Arising advances, for example, 3D winding around and brilliant materials, push the limits of what is conceivable. 3D winding around methods include the joining of filaments in three aspects, making textures with improved primary honesty and extraordinary tasteful conceivable outcomes. Shrewd materials coordinate innovation into woven textures, opening up new boondocks in fields like wearable hardware and medical care.

All in all, woven texture remains as a demonstration of human imagination, craftsmanship, and development. From old handloom methods to present day, innovatively progressed processes, the specialty of winding around keeps on forming the texture of our lives. Whether as regular pieces of clothing, wonderful embroideries, or state of the art materials, woven texture winds around together the strings of custom, culture, and progress, making a rich and various embroidery that traverses the globe. As we disentangle the tales implanted in each woven string, we gain a more profound appreciation for the creativity and meaning of this immortal material.

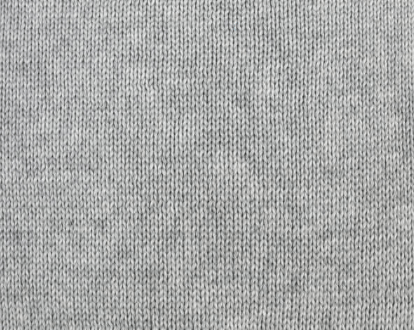

Knitted Fabrics–

Weaved texture, a wonder in material designing, typifies the specialty of making interconnected circles from yarn to create a flexible and stretchable material. Dissimilar to woven textures, which are built through the entwining of opposite yarns, weaved textures are framed by entwining yarns in a constant way. This extraordinary development gives unmistakable qualities to sewed materials, making them flexible, agreeable, and appropriate for a great many applications.

The historical backdrop of sewing can be followed back to old times when hand-weaved pieces of clothing were created for warmth and insurance against the components. Throughout the long term, weaving developed from a manual, tedious interaction to a motorized industry, with sewing machines equipped for creating textures at a lot quicker pace. Today, sewed textures are fundamental to the design business, activewear, and different specialized applications.

One of the most notable instances of weaved texture is pullover, generally utilized in the creation of Shirts, sports apparel, and underpants. Jersey texture is made utilizing a solitary weave development, bringing about a smooth, stretchy, and lightweight material. Its adaptability and breathability pursue it a famous decision for relaxed dress, while progressions in innovation have prompted the improvement of execution shirts with dampness wicking properties for sports and open air exercises.

Cashmere, a rich and delicate material, embodies the top notch quality reachable through sewing. Gotten from the fine hair of cashmere goats, this sensitive yarn is fastidiously weaved into textures that radiate warmth and style. Cashmere sweaters, scarves, and cloaks are valued for their delicateness and protecting properties, exhibiting the capacity of weaved textures to give both solace and style.

As of late, consistent weaving innovation has upset the development of articles of clothing, taking out the requirement for conventional creases and improving the general solace of dress. Consistent sewing machines can make whole articles of clothing in one piece, diminishing waste and advancing proficiency. This development has prompted the ascent of consistent sports clothing, underpants, and even footwear, where the shortfall of creases adds to a smooth and ergonomic fit.

Weaved textures likewise assume an essential part in the realm of execution clothing. Textures designed for dampness the executives, pressure, and breathability are ordinarily weaved to take care of the requests of competitors and wellness fans. For instance, pressure socks, which give designated strain to further develop blood flow, are much of the time weaved utilizing specific machines and strategies. The stretch and recuperation properties of weaved materials make them ideal for articles of clothing that need to oblige dynamic body developments.

Past style and active apparel, sewed textures have tracked down applications in the clinical field. Consistent, weaved pressure pieces of clothing are used in the treatment of conditions like lymphedema and venous deficiency. The delicate tension applied by these articles of clothing helps with lessening expanding and advancing blood flow. Sewn gauzes, produced using delicate and stretchable materials, offer an agreeable option for wound care, adjusting to the shapes of the body.

In the domain of inside plan, weaved textures add to the production of comfortable and welcoming spaces. Stout weave covers and tosses, produced using thick yarns and huge needles, add a bit of warmth and surface to living spaces. The material nature of these weaved materials changes a room, welcoming a feeling of solace and unwinding.

Innovative progressions have pushed the limits of what is conceivable with sewn textures. Shrewd materials, which incorporate electronic parts into materials, frequently influence the stretchability of sewn structures. For instance, sewed textures with implanted conductive strings can be utilized in the advancement of wearable innovation, for example, savvy clothing that screens physiological boundaries or intuitive materials that answer contact.

Economical practices have likewise advanced into the domain of weaved textures. The utilization of reused yarns and eco-accommodating strands in weaving lines up with the developing attention to natural effect in the material business. Sewn pieces of clothing produced using natural cotton or reused polyester grandstand a guarantee to decreasing the biological impression of design.

All in all, sewed texture remains as a demonstration of the flexibility and development inside the material business. From the comfortable hug of a cashmere sweater to the elite exhibition usefulness of consistent sports clothing, sewed textures have woven themselves into the texture of our day to day routines. The blend of customary craftsmanship and state of the art innovation keeps on pushing the limits of what is reachable with weaved materials. As we wonder about the solace, flexibility, and tasteful allure of sewn textures, we witness the continuous development of this ageless and dynamic material.